Extractly cuts costs for DoorCo Manufacturing

)

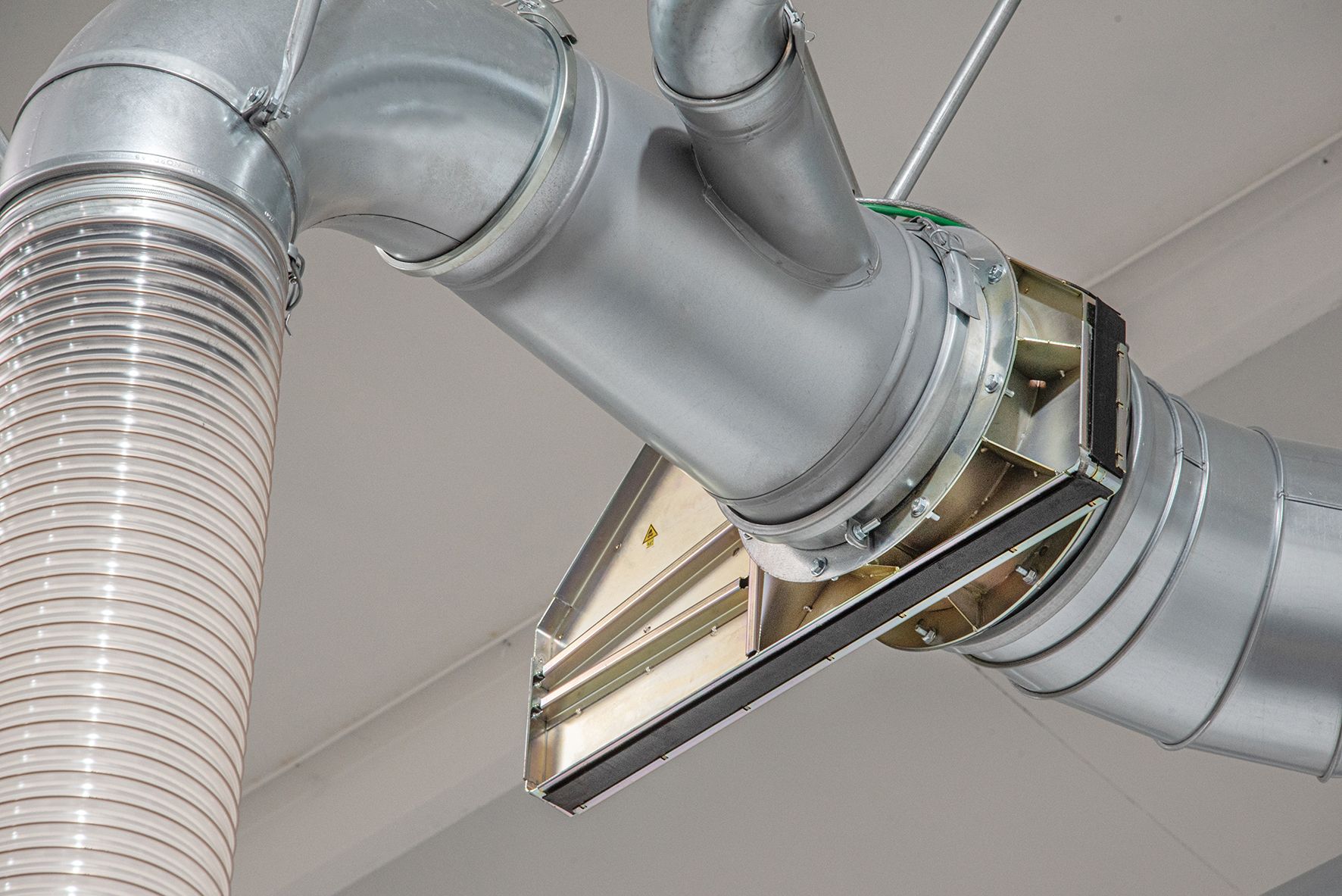

Extractly Ltd has played a key part in DoorCo’s latest development plans with the supply and installation of an energy-saving, Ecogate-controlled, dust extraction system at the company’s new manufacturing facility in Thorne, near Doncaster, South Yorkshire.

With head office and existing manufacturing facilities in Macclesfield, Cheshire, DoorCo Ltd is already acknowledged as the UK’s leading independent manufacturer and supplier of high-quality composite doors. At Thorne, with close to 7,500m2 of space available to develop its manufacturing capacity into the future, DoorCo has made a significant investment in state-of-the-art production machinery for its new premium door brand which combines a machined timber core with a thermoplastic skin.

The new facility is initially opening its doors with two high-performance Biesse machining centres, but DoorCo already has plans in place to double capacity as the site develops. Extractly Ltd services and maintains the extraction systems at DoorCo’s Macclesfield facility, and last year installed a new filter unit to serve the composite door manufacturing area. With an air flow capacity of 35,000m3/hour, to remove fibreglass and PVC waste created by three CNC machines, a beam saw, and an edgebander, the extraction is controlled and optimised by an energy-saving Ecogate® system.

Following on from the successful installation at Macclesfield, Extractly’s sales director, Jake Oldfield, was invited to put forward a proposal for provision of a new extraction system at the Thorne facility. “We were very pleased to be awarded the contract to install the system at Macclesfield, and delighted to be able to follow that up with a further installation at the new Thorne facility”, Jake acknowledged. “DoorCo is an innovative company, with a reputation for producing the highest quality products, and we are proud to be recognised as a supplier of equipment that meets their high standards. Thorne was a blank canvas, but it was imperative that the system should be designed to be powerful enough, and easily expandable, to match DoorCo’s manufacturing growth projections. The system also had to be as economic to run with just two machines in operation as it would be with four or more machines – and without any compromise on extraction power.”

Following on from the successful installation at Macclesfield, Extractly’s sales director, Jake Oldfield, was invited to put forward a proposal for provision of a new extraction system at the Thorne facility. “We were very pleased to be awarded the contract to install the system at Macclesfield, and delighted to be able to follow that up with a further installation at the new Thorne facility”, Jake acknowledged. “DoorCo is an innovative company, with a reputation for producing the highest quality products, and we are proud to be recognised as a supplier of equipment that meets their high standards. Thorne was a blank canvas, but it was imperative that the system should be designed to be powerful enough, and easily expandable, to match DoorCo’s manufacturing growth projections. The system also had to be as economic to run with just two machines in operation as it would be with four or more machines – and without any compromise on extraction power.”

Unquestionably, the key to the success of Extractly’s latest installation for DoorCo is once again the inclusion of energy-saving Ecogate® ‘on-demand’ extraction optimisation technology. With two CNC machines in continuous operation the system needed to have an extraction capacity of around 8,000m3/hour. However, to future proof the system, Extractly proposed a filter unit capable of handling a minimum of 16,000m3/hour, powered by a 37kW main fan. “Ordinarily, this would be like a ‘sledgehammer to crack a nut”, explained William Kenyon, Extractly’s technical director and specialist Ecogate® engineer. “In a traditional system the extraction fan would operate at full power, all day, every day, and a 37kW fan would typically consume around 70,000kW of electricity per year. At DoorCo, however, the predicted electricity consumption is calculated to be substantially lower than this; even when more machines are added and output is doubled.”

With Ecogate® technology controlling the extraction system, the fan will only operate when machining is in progress. The Ecogate® greenBOX controller continuously monitors machine usage and adjusts fan speed accordingly, in real-time, to match every change in extraction demand. The fan will always run at the minimum speed necessary to provide the exact extraction required to remove woodwaste from the workstations and to maintain transport velocities through the system to ensure no dust can settle in the ductwork. “It’s the ability to accurately monitor demand and continually vary fan speed that achieves the energy savings,” explains William Kenyon, “along with some help from the laws of physics!”

Ecogate® technology takes advantage of the ‘Fan Affinity Laws’ which, when applied to an extraction system design, can substantially reduce energy consumption. Fan speed increases and decreases in proportion with the extraction volume demanded, but the change in energy required to power the fan varies by the cube of the speed change; effectively, just a 10% reduction in fan speed will reduce electricity consumption by approximately 27%, and a reduction of 20% in fan speed can save almost 50% on the cost of electricity. On average, Ecogate® installations around the world are saving manufacturers up to 68% off their electricity bills.

In conclusion, Head of Operations at DoorCo, Mark Towers, commented: “Our business has always invested in 'the best equipment for the job' and, at Doorco, a reliable, efficient dust extraction system is as important to us as the latest CNC machining centres we've installed at our Thorne factory, and I can’t fault the efficiency of the system Extractly has installed for us."

)

)

)

)

)

.jpg)

.png)

.jpg)